When your Hydraulic Cylinder suddenly stops working, it can bring productivity to a halt. But don't panic - by systematically checking these three key systems, you can quickly identify and resolve the issue.

Inspect the Hydraulic Power Source (Pump & Tank)

1.1 Hydraulic Fluid Level Check

Visual Inspection: Locate the sight glass or dipstick on the reservoir. The fluid level should be between the MIN/MAX marks.

Critical Note: A low level often indicates leaks in the system. Look for puddles or wet components.

Action:

Top up only with manufacturer-approved fluid (mixing viscosities can cause damage)

If fluid appears milky (emulsified) or contains visible particles, complete replacement is needed

1.2 Suction Line & Filter Examination

Warning Signs:

Whining noise from pump (cavitation)

Collapsed suction hose (visible vacuum deformation)

Filter clogging indicator (if equipped) showing red

Pro Tip: Always keep spare filters on hand. For critical systems, consider installing a vacuum gauge to monitor suction restriction.

Control System Diagnosis (Valves & Signals)

2.1 Input Signal Verification

Multimeter Testing:

24V DC systems should show 22-26V at coil terminals

Current draw should match manufacturer specs (typically 0.5-1.5A)

Common Failures:

Corded connectors in outdoor equipment

Broken wires at flex points

Failed relays in control circuit

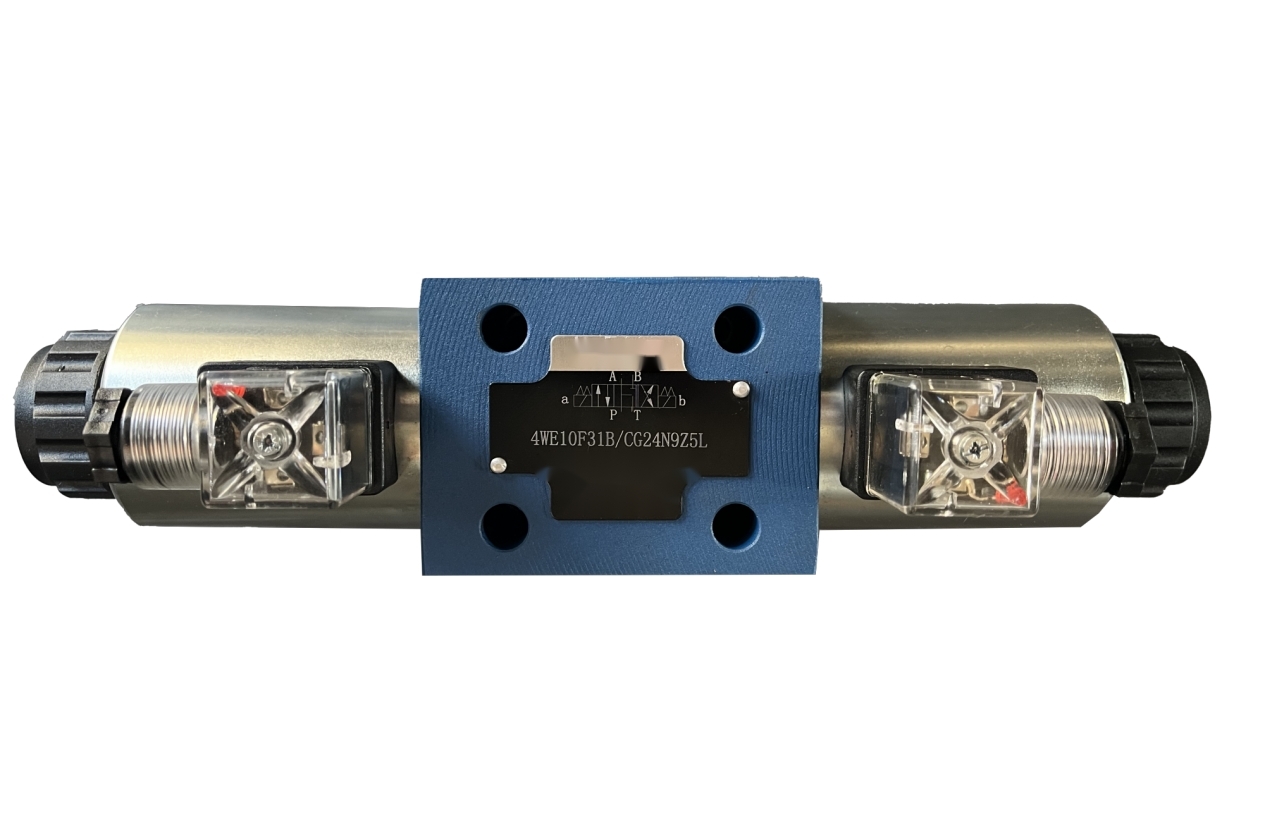

2.2 Directional Valve Analysis

Pressure Testing:

Pilot pressure requirements vary (typically 100-500 psi)

Use a tee-fitting to monitor pressure during operation

Solenoid Checklist:

Coil temperature should be warm (40-60°C) not hot (>80°C indicates problems)

Audible "click" should occur within 0.5 seconds of energization

Expert Technique:

For intermittent issues, use a mechanic's stethoscope to listen for partial engagement

Portable valve testers can verify spool movement without disassembly

Cylinder & Load Inspection3.1 Hose & Connection Check

Pressure Testing Method:

Install gauges at both cylinder ports

Compare pressure readings during operation - significant differential indicates restriction

Leak Detection:

Use paper towel around fittings (look for weeping)

UV dye additives make leaks visible under black light

3.2 Internal Leakage Test

Safety First: Always lockout/tagout power and relieve all pressure before disconnecting lines

Quantitative Method:

Measure flow rate from disconnected port

10% of system flow indicates seal failure

Alternative Approach:

Monitor cylinder creep under load

1"/minute drift suggests internal leakage

3.3 Mechanical Load Verification

Alignment Checks:

Use laser alignment tools for long-stroke cylinders

Check for twisted loads with dial indicators

Bearing Inspection:

Pivot points should move freely without play

Look for Brinelling (indentations) in bearing surfaces

Proactive Maintenance Tips

- Fluid Analysis: Quarterly oil sampling can predict 80% of hydraulic failures

- Contamination Control: Install a beta-rated filter with ≥200 rating

- Preventive Replacements: Change seals every 50,000 cycles in high-use applications

- Training: Operators should recognize early warning signs like slower operation or unusual noises

Final Thought: Remember that 70% of hydraulic failures stem from fluid contamination. Investing in proper filtration and regular maintenance will prevent most sudden cylinder failures before they occur.

Summary

This comprehensive guide outlines a systematic three-step approach to diagnose hydraulic cylinder failures, progressing from power source verification to control system inspection and finally mechanical component checks. Each section provides professional testing methods, quantitative thresholds, and proactive maintenance strategies. The expanded content includes advanced diagnostic techniques, safety considerations, and predictive maintenance approaches not covered in the original version, making it valuable for both novice technicians and experienced hydraulic specialists.

Media Contact

Company Name: Qingdao Micro Precision Machinery Co., Ltd.

Email: Send Email

Phone: +86-15589891818

Address:No. 438, Wangsha Road, Chengyang District

City: Qingdao

Country: China

Website: https://www.mpmmachine.com/